In recent years, 3D printing has quietly found a foothold in many industries, offering benefits through rapid prototyping, reduced manufacturing costs, and custom production. One unexpected area where it's beginning to make a real difference is the gambling industry. From poker chips to casino accessories, 3D printing is gradually transforming how small and medium-sized casinos manage operational expenses and deliver personalized experiences to customers.

Cutting Costs Through In-House Manufacturing

For most businesses, the appeal of 3D printing begins with its ability to drastically cut production costs.

Casinos, especially smaller or independently owned establishments, are no different. Traditionally, items like poker chips,

card holders, roulette wheel components, or custom dice are ordered in bulk from third-party manufacturers—often overseas.

This process involves not only high upfront costs but also long lead times, minimum order quantities, and shipping expenses.

By contrast, 3D printing enables these casinos to produce the items they need on-site or through local fabrication services,

using affordable materials like PLA or ABS plastic. A single design file can be reused, modified, or scaled as needed without

the need for tooling or molds. If a poker chip goes missing or a part breaks, it can simply be reprinted in-house within hours—no

need to wait for replacements to arrive.

Increasing Adoption Among Smaller Casinos

While large casino chains have the resources to continue using traditional manufacturing methods, smaller casinos have been

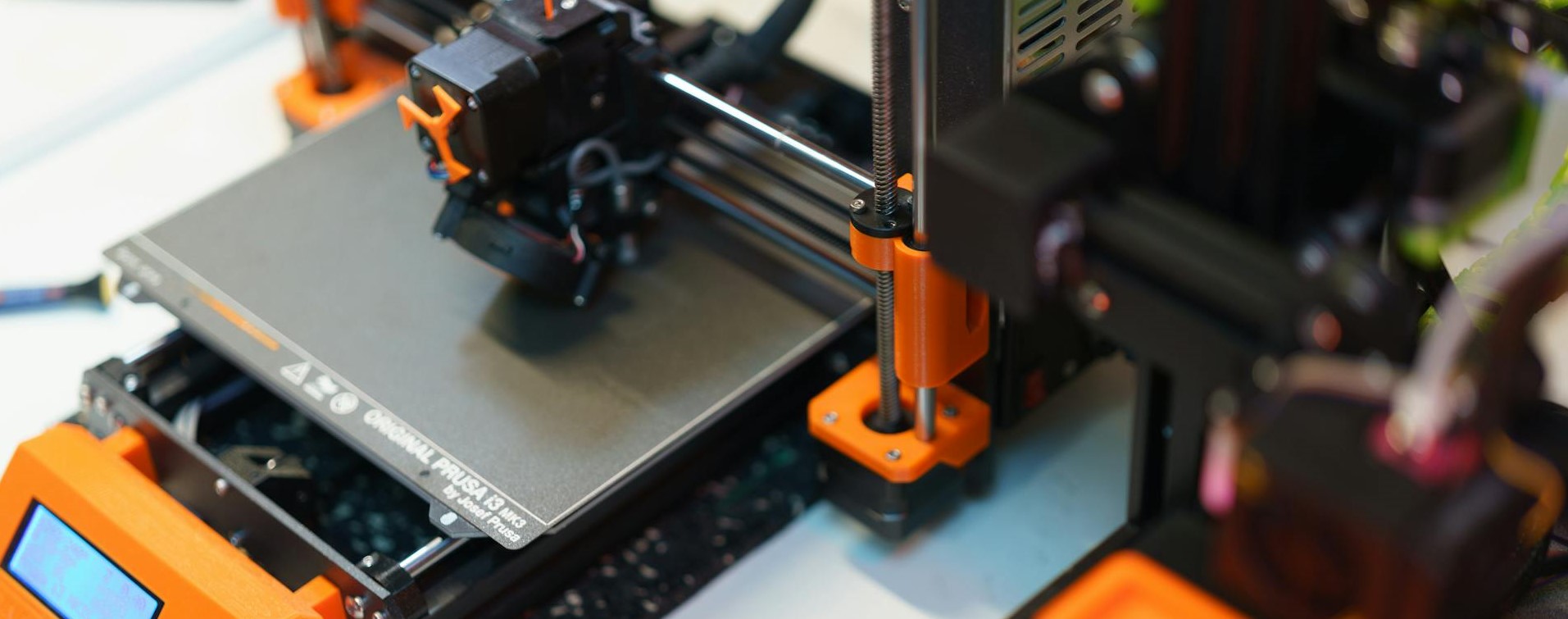

quicker to explore 3D printing as a flexible alternative. Many now rely on desktop 3D printers for low-volume production of

key gaming accessories. For these businesses, the ability to customize products in-house, adjust designs on the fly, and avoid

large inventories has proven to be both practical and cost-effective.

In fact, this shift toward 3D printing has also opened up creative opportunities for these casinos.

They can design unique themes, brand elements, or special-edition items to match seasonal promotions or

private events—all without breaking their budget.

Improved Poker Chip Design at a Lower Cost

One of the most noticeable examples of 3D printing’s influence is in poker chip production.

Traditional clay or ceramic chips can be expensive, especially when ordering custom designs.

With 3D printing, casinos and even individuals hosting poker nights at home can produce poker

chips that are both visually appealing and far more affordable.

Though they may not match the weight or feel of premium casino chips, they serve well for casual use and

themed events. Importantly, they can be made in any quantity, small or large.

How 3D Printing Works in This Context

At its core, 3D printing builds objects layer by layer using digital design files. To create a poker chip, for example,

a designer would first model the object using CAD software,the model is then sliced into layers, and the printer deposits material accordingly.

Those with no design experience can still create custom items by downloading open-source files from trusted repositories.

Where to Find Poker Chip Models for Personal or Casino Use

For anyone interested in printing their own poker chips,a good starting point is downloading pre-designed models.

A recommended option is this poker chip model available on Cults3D:

:format(webp)/https://fbi.cults3d.com/uploaders/41640997/illustration-file/15161d83-3b4d-4f56-8703-414394374769/Poker-chips.png)

👉 Poker Chips STL

This model is designed with a practical size and optimized for printing on standard 3D printers. It's customizable, meaning users can add their own colors, or stickers.

The Future of 3D Printing in Gambling

While the technology isn’t replacing traditional manufacturing in high-end casinos anytime soon, it's quiet adoption by smaller gambling establishments signals a broader trend toward decentralization and digital fabrication. For casinos looking to cut costs without sacrificing quality, 3D printing offers a practical path forward. And for poker enthusiasts at home, it’s never been easier to bring a touch of professional flair to a casual game night.